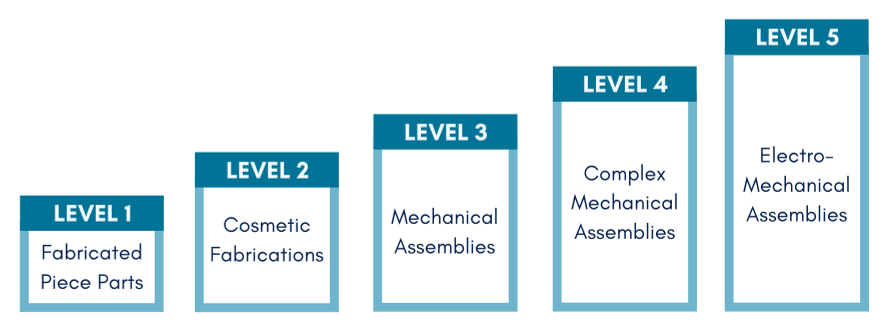

Our Complexity Model is a tool that defines and documents our core business capabilities and enables us to plan our resources around a variety of projects. We understand the value of creating a synergy between SPM and our customers, and this tool facilitates mutual alignment and understanding between us.

We can be flexible and provide uniquely tailored Design for Manufacturability (DFM) solutions through documenting our capabilities, understanding resource requirements, and planning the timely purchasing of materials/BOM items.

Single piece parts

≤ Class B paint

≤ Class B plating

Weld

PEM hardware

Standard materials

Work instructions

Cosmetic req.

≥ Class A req.

Anodize plating

304 #3 finish w/ PVC

Grained material

PVC coated material

Silk Screening

Paint-class A+

Specialized Packaging

External Doors/Covers

Control panels

Hoods

Faceplates

Chassis front

Instrument panels

Work Instructions

Assembly required

Fixtures

Purchased Items

Qty. of Parts ≤10

BOM items ≤25

Welding multiple pcs

Fasteners

Mechanical fasteners

Gaskets

Standard packaging

Work Instructions

LEVEL 3 PLUS

Specialty items

Qty. of Parts >10

BOM items >25-100

Tubing/Angle

Inventory Mgmt.

Specialized Packaging

Work Instructions

LEVEL 4 PLUS

Qty. of Parts

Passive Components

Testing

Logistics

Inventory Mgmt.

Specialized Packaging

Work Instructions

New Product Introduction Process

Design for Manufacturability

Rapid Prototyping

Inventory Management

Supply Chain Management

Transportation

Logistics