We offer a wide range of value-added services to provide you with cost savings, especially through our inventory and supply chain management programs. Our services eliminate the need for intervention from third-party vendors and service providers, and we keep them in compliance with and certified to ISO 9001:2015 standards.

Whether you’re in need of New Product Introduction, Design for Manufacturability support, Rapid Prototyping, inventory management, supply chain management, transportation, or logistics, SPM has you covered.

From design to fabrication, our New Product Introduction Process (NPI) helps our customers accelerate their entrance into new or developing markets ahead of the competition. With NPI, you can gain a significant competitive advantage in your target market while reducing your capital investment in manufacturing.

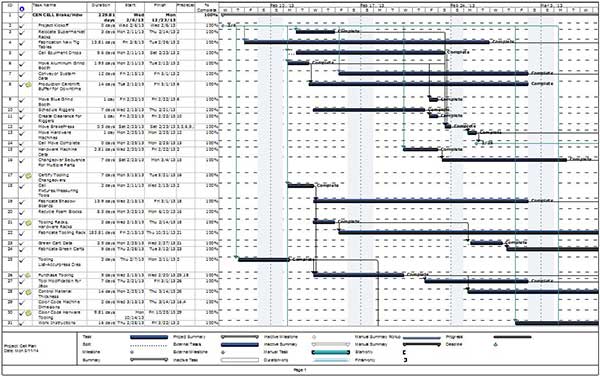

Our Engineering team has the resources and experience to work on our customers’ products and efficiently transition their product lines to our plant floor. We work closely with your team through all phases of the NPI process, including project mapping, prototyping, simulation, and project execution.

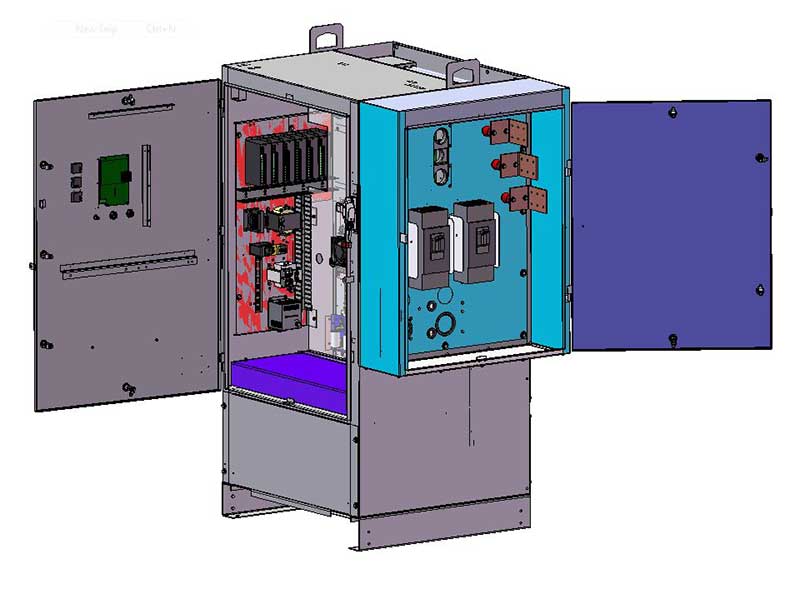

At Special Products & Mfg., Inc., we are experienced in all phases of precision sheet metal fabrication. Our experienced Engineering team will work with you to help you get the most out of your product design.

When our planners and programmers review our customers’ parts, they search for possible problem points or opportunities for failure. If a problem is identified, they will offer DFM solutions to the customer. We can also make suggestions to improve the design of our customers’ products for better performance, faster manufacturing, or better cost savings.

When our customers need to see a prototype of their parts fast, our Rapid Prototyping service coordinates the quick manufacturing and delivery of high-quality prototypes. With our brilliant FasTrak system, we measure lead-time in days and can typically go from design to production in as little as one business week. An automated FTP recovery system notifies us every half hour if new files are dropped so that we can begin producing prototype production immediately. This program is only available to a trusted selection of our customers.

As part of our value-added services, At SPM, we are experts in inventory management. We have a 10,000 square-foot offsite inventory warehouse, as well as additional inventory space in our Rockwall and Austin facilities. We can base our inventory management program within our own facility, our customers’ facilities, or both.

Our inventory management system reduces your overhead costs on inventory and facility space, as well as minimizes excess inventory and product obsolescence costs. We offer a variety of inventory management techniques including KanBan, Just-In-Time (JIT), Built-to-Schedule, and Vendor-Managed Inventory (VMI). Each of these can be completely customized to suit your strategic plan and goals.

Our Supply Chain Management (SCM) system coordinates the procurement process and manufacturing processes to ensure that raw materials and Bill of Materials (BOM) items arrive Just-In-Time. We have the systems, knowledge, and experience to help set up, improve, or transition a supply chain for our customers.

By capitalizing on raw materials through bulk purchasing, we reduce the overall cost exposure to our customers. We also work collaboratively with suppliers to understand their constraints and map our processes to drive extra costs out of the supply chain. Our SCM system produces valuable benefits such as new efficiencies, increased collaboration, and lower costs for our customers.

Getting your products delivered safely and damage-free for our customers is our top priority. We have a fleet of vehicles to serve our local and regional customers and require our drivers to obtain a Commercial Driver’s License (CDL) and show a high degree of experience. We offer hotshot and long-haul shipping, as well as common carrier transportation throughout the United States and across the globe.

SPM’s logistics service handles the production, packaging material handling, inventory, information flow, warehousing, and security of our customers’ products. Our systemic approach to understanding your needs enables us to define a logistics solution that’s just right for you. Dock-to-stock, direct to customer sites, direct to distribution, and multiple shipping points are all available through our logistics service.